E-posta biçimi hatası

emailCannotEmpty

emailDoesExist

pwdLetterLimtTip

inconsistentPwd

resetAccountPassword

forTheAccount

pwdLetterLimtTip

inconsistentPwd

resetSuccess

resetSuccessTips

login

Haberler

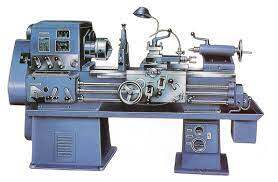

The Daily Maintenance of the Lathe can Keep its Accuracy as New

2022-07-05 18:39:42

Before shift:

- Clean the dust on the exposed guide rail surface and sliding surface of the machine tool and add oil;

- Lubricate all parts as required;

- Check the position of each handle;

- Empty vehicle test run.

In class:

- Strictly abide by the operating procedures;

- Pay attention to the operation of the machine tool at any time during operation, and deal with abnormalities in time.

After shift:

- Clean all iron filings;

- Clean all parts of the machine tool;

- Part return.

weekend:

- Wipe all parts of the machine tool comprehensively, and keep the paint visible and the iron visible;

- Check whether the fasteners are loose;

- Check and clean wool and felt;

- Lubricate all components.

Daily maintenance of CNC lathe

- Clean and lubricate all guide rail surfaces every day. Machine tools with automatic lubrication system should regularly check and clean the automatic lubrication system, check the oil volume, add lubricating oil in time, and check whether the oil pump starts and stops regularly;

- Check whether the automatic lubrication system of the headstock works normally every day, and replace the lubricating oil of the headstock regularly;

- Pay attention to check whether the cooling fan in the electrical cabinet works normally, whether the air duct filter screen is blocked, and clean the attached dust;

- Check the spindle drive belt and adjust the tightness;

- Pay attention to check the tightness of the guide rail insert and adjust the clearance;

- Pay attention to check whether the oil pump in the oil tank of the hydraulic system of the machine tool has abnormal noise, whether the working oil level is appropriate, whether the indication of the pressure gauge is normal, and whether the pipelines and joints have leaks;

- Pay attention to check whether the guide rail and the protective cover of the machine tool are complete and effective;

- Pay attention to check the mechanical accuracy of all moving parts to reduce the shape and position deviation;

- Clean the machine tool after work every day, clean the iron filings, and wipe the coolant on the guide rail to prevent the guide rail from rusting.

Daily maintenance of vertical lathe

Before work:

First, check the shift notebook;

Second, refueling shall be carried out in strict accordance with the "lubrication chart" of the equipment, so as to achieve timing, quantity and quality;

Third, for equipment that has been shut down for more than 8 hours, when the equipment is not started, turn it low for 3-5 minutes to confirm whether the lubrication system is unblocked and whether all parts operate normally before starting to work.

At work:

Often check the operation of all parts of the equipment and the working condition of the lubrication system. If there is any abnormal condition, immediately notify the inspection staff to deal with it;

It is strictly forbidden to place tools, workpieces, metal objects and pedals on the guide rail surface and protective cover.

After work:

Wipe the iron filings and coolant on the guide rail surface, and there is no black oil on the lead screw and polished rod;

Clean the iron filings and sundries around the equipment;

Fill in the equipment shift record carefully.

Make a purchase of centre lathe axis, used trak lathe, galaxy cnc lathe machine from China, you can get them at a good price if you have a large quantity. We hope to be your long-term partner.

Bize Ulaşın