E-posta biçimi hatası

emailCannotEmpty

emailDoesExist

pwdLetterLimtTip

inconsistentPwd

pwdLetterLimtTip

inconsistentPwd

Haberler

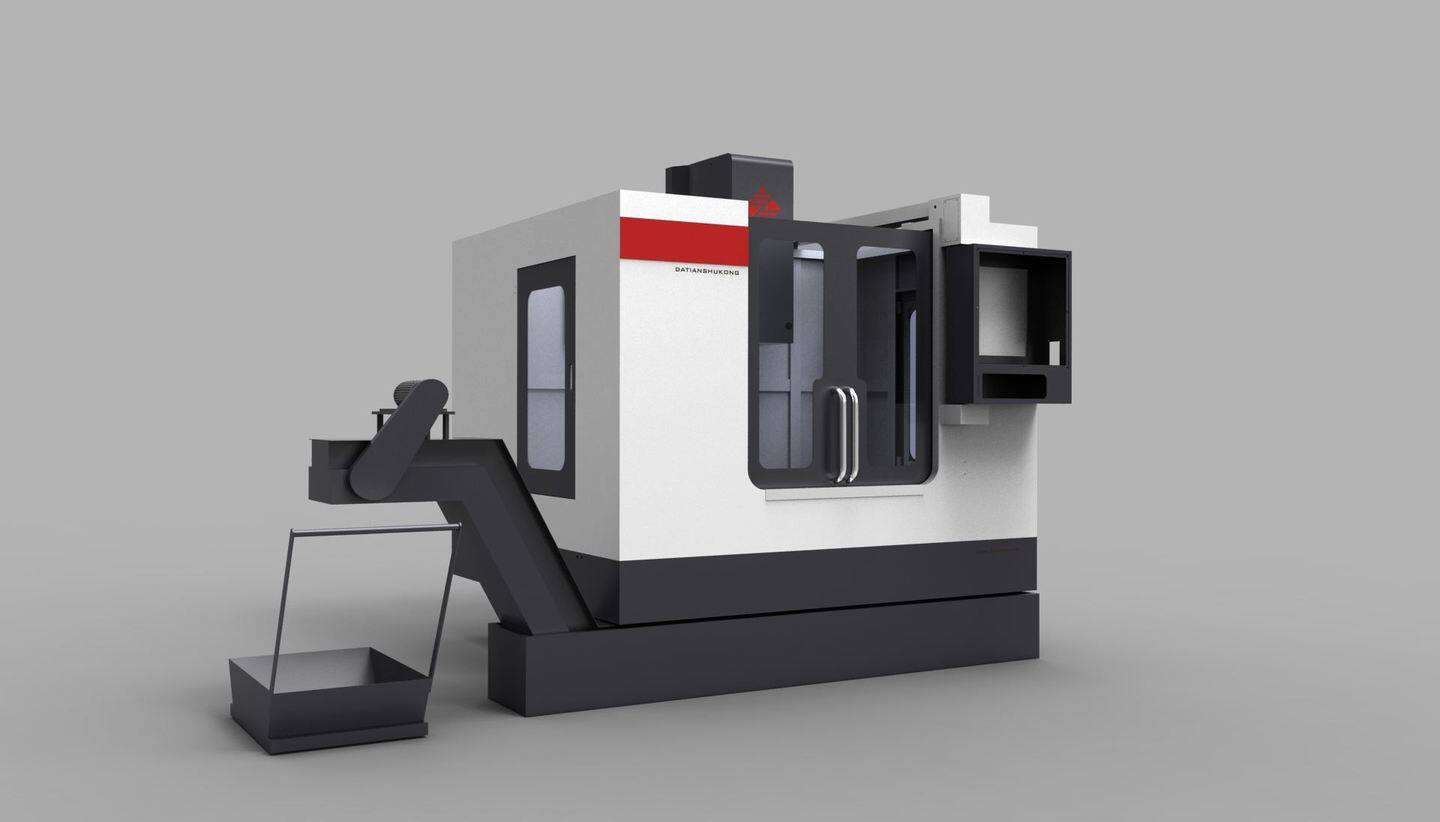

Application of Several Commonly Used CNC Milling Machines

All digital AC servo drive for CNC milling machine. The machine tool consists of six main parts That are, the lathe bed, milling head, worktable, cross feed, lifting table, cooling, and lubrication. The internal layout of the machine bed is reasonable and has good rigidity. Four adjusting bolts are set on the base to facilitate the horizontal adjustment of the machine tool. The cutting fluid reservoir is set inside the machine tool base.

Main uses of CNC milling machine:

- Box-type parts

There are many box parts. Generally, a multi-station hole system and plane processing are required. The requirements for accuracy are high, especially the requirements for shape accuracy and position accuracy are strict. Generally, milling, drilling, expanding, boring, reaming, spot facer, tapping, and other steps are required. There are many tools required. It is difficult to process on ordinary machines. There are many sets of tooling, which need to be clamped and aligned many times. There are many times of manual measurement, and the accuracy is not easy to guarantee. One-time installation on the CNC milling machine can complete 60% - 95% of the process content of the ordinary machine tool. The parts have good accuracy consistency, stable quality, and a short production cycle.

- Disc, sleeve, and plate parts

There are planes, curved surfaces, and hole systems on the end face of this kind of part. Radial holes are often distributed in the radial direction. A vertical CNC milling machine should be selected for the disc, sleeve, and plate parts whose processing parts are concentrated on a single end face, and a horizontal CNC milling machine should be selected for parts whose processing parts are not located on the surface of the same direction.

- Cams

These kinds of parts include various curved disc cams, cylindrical cams, conical cams, end-face cams, etc. during machining, three-axis, four-axis or five-axis CNC milling machines can be selected according to the complexity of the cam surface.

- Integral impeller

Impellers are commonly used in Aeroengine compressors, air compressors, ship underwater thrusters, etc. in addition to the characteristics of general surface machining, they also have many special machining difficulties, such as narrow NC milling machine path, and the tool is easy to interfere with the machined surface and adjacent surfaces. The blade surface is a typical three-dimensional space surface, and the CNC milling machine with more than four axes linkage can be used to process such a surface.

- Irregular-shaped parts

Special shaped parts refer to parts with an irregular shape, such as NC milling machine support and shift fork. Most of them are processed by multi-station mixed processing of key points, lines, and surfaces. Due to the irregular shape, the general machine tool can only adopt the principle of decentralized processing, which requires more tooling and a longer cycle. Using the characteristics of multi-station point, line, and surface mixed processing of CNC milling machine, most or even all of the working procedures can be completed.

We are a best hobby cnc milling machine, bench top cnc milling machine, open source cnc milling machine wholesaler, our products satisfy our customers. And we want to be your long-term partner, any interests, welcome to contact us.